Precast concrete parking structures have been designed for the IBC-prescribed minimum live load of 40 psf with the introduction of IBC 2000, and this provision is still contained in IBC 2021 and ASCE 7-22. Both these codes prescribe the 40 psf uniform live load with a nonconcurrent 3.0 K concentrated load applied over a 4½” x 4½” area. This concentrated load is commonly called a wheel load, but its real purpose is to account for possible wheel jack loading for heavy 10,000# vehicles as described in the Commentary to ASCE 7-22, Section C.4.10.1.

With marked increase in frequency Nitterhouse Concrete Products, Inc. (NCP) receives inquiries regarding loading from Electric Vehicles (EV) in contrast with typical gasoline powered vehicles when designing the elevated levels of precast parking structures. As of the writing of this paper we at NCP are of the opinion that the current 40 psf vehicular live load provisions are acceptable. However, because the current IBC building code and ASCE design code do not address this question the information we are providing herein is strictly our opinion for purposes of discussion and is not intended to be authoritative. It is the responsibility of the design community to choose the design parameters it deems appropriate when preparing design drawings and specifications. What follows represents how we have reached the conclusion that continuing to design using a 40 psf vehicular live load is both reasonable and safe.

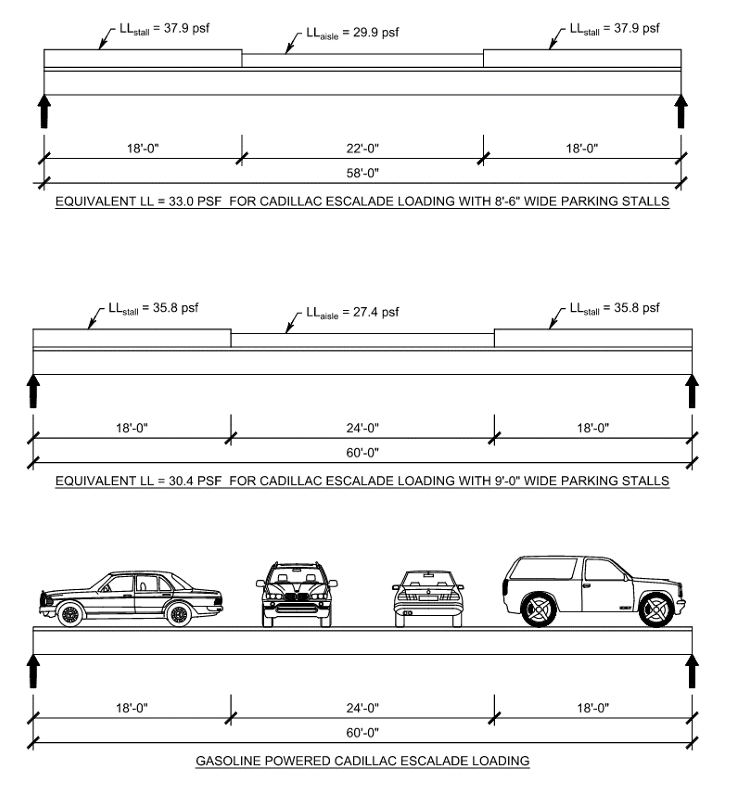

The first consideration is the weight of parked vehicles. Let’s conservatively select a large automobile such as the Cadillac Escalade weighing about 5,800# with a footprint of approximately 6.76’ x 17.66’. Because a typical parking space is 9’-0” x 18’-0”, the unit weight within a parking space is more accurately 5,800# / (9.0’)(18.0’) = 35.8 psf. Even when parking spaces are reduced to 8’-6” x 18’-0” as is common in some urban parking structures, valet parking, or rental car parking the unit weight marginally increases to 5,800# / (8.5’)(18.0’) = 37.9 psf. Both these values are less than the 40 psf minimum live load prescribed by IBC.

If we focus on the drive aisle it is reasonably probable that vehicles could be lined up end-to-end, especially when exiting the structure after a major event. The width of two-way drive aisles is typically 24’-0”, or 12’-0” per drive lane. Thus, the unit weight within the drive aisle is 5,800# / (12.0’)(17.66’) = 27.4 psf. Even in tighter urban settings the two-way drive aisles are reduced to 22’-0”, or 11’-0” per drive lane, resulting in a unit weight within the drive aisle of 5,800# / (11.0’)(17.66’) = 29.9 psf. Again, both these values are less than the 40 psf minimum live load prescribed by IBC.

Now let’s consider a combination of the loading conditions outlined in the first consideration to arrive at an equivalent uniform loading based upon bending moments, since that is what is prescribed in the previously mentioned codes. As a reminder, this conservatively assumes a Cadillac Escalade in every parking stall, with Cadillac Escalades bumper-to-bumper in the drive aisle. From the perspective of probability neither of these conditions are likely, except for an automobile dealership. These are summarized graphically on Page 2 below, where the equivalent uniform live load is 30.4 psf or 33.0 psf depending upon the width of the parking stalls. Both values are significantly less than the 40 psf minimum live load prescribed by IBC.

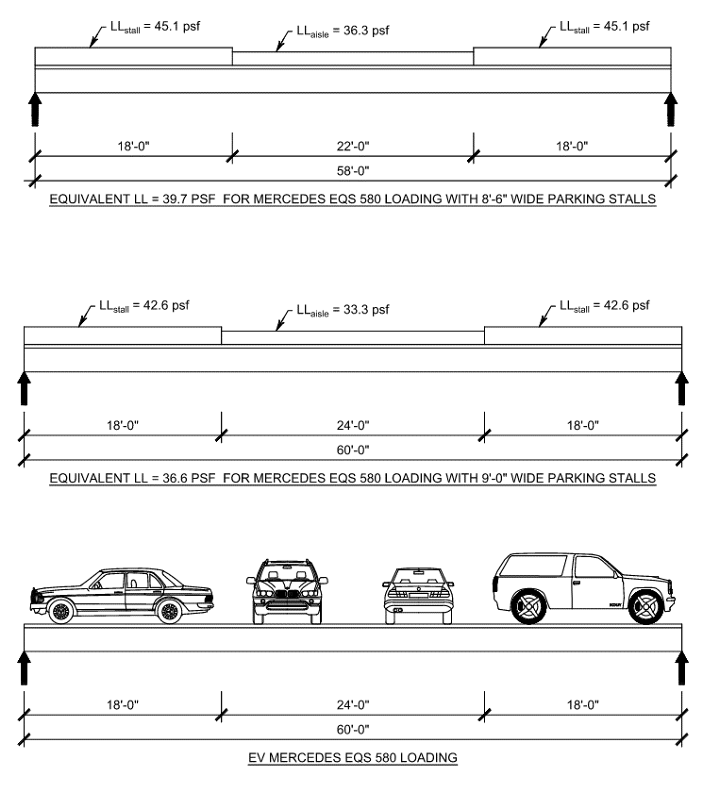

But we have not yet addressed the weights of EV’s. So, our second consideration is the weight of parked EV’s. As before, let’s conservatively select a large EV such as the Mercedes EQS 580 weighing about 6,900# within a footprint of approximately 6.32’ x 17.28’. Because a typical parking space is 9’-0” x 18’0”, the unit weight within a parking space is more accurately 6,900# / (9.0’)(18.0’) = 42.6 psf. Even when parking spaces are reduced to 8’-6” x 18’-0” as is common in some urban parking structures, the unit weight marginally increases to 6,900# / (8.5’)(18.0’) = 45.1 psf. We observe that both these values are more than the 40 psf minimum live load prescribed by IBC.

If we focus on the drive aisles it is reasonably probable that vehicles could be lined up end-to-end. The width of two-way drive aisles is typically 24’-0”, or 12’-0” per drive lane. Thus, the unit weight within the drive aisle is 6,900# / (12.0’)(17.28’) = 33.3 psf. Even in tighter urban settings the two-way drive aisles are reduced to 22’-0”, or 11’-0” per drive lane, resulting in a unit weight within the drive aisle of 6,900# / (11.0’)(17.28’) = 36.3 psf. Both these values are less than the 40 psf minimum live load prescribed by IBC.

Now let’s consider a combination of the loading conditions outlined in the second consideration to arrive at an equivalent uniform loading based upon bending moments, since that is what is prescribed in the previously mentioned codes. As a reminder, this conservatively assumes a Mercedes EQS 580 in every parking stall, with Mercedes EQS 580’s bumper-to-bumper in the drive aisle. From the perspective of probability neither of these conditions are likely, except for an automobile dealership. These are summarized graphically on Page 4 below, where the equivalent uniform live load is 36.6 psf or 39.7 psf depending upon the width of the parking stalls. Both values are still less than the 40 psf minimum live load prescribed by IBC.

While these first and second considerations are improbable it is still possible for them to occur, especially on a localized sampling of individual members such as double tees or maybe beams and columns. Still, we have demonstrated that both gasoline powered vehicles and EV’s fit within the present 40 psf uniform loading parameters. Furthermore, the average gasoline powered vehicle only weighs about 4,100#, nearly 30% less than a 5,800# Cadillac Escalade. Similarly, the average EV only weighs about 4,600#, nearly 33% less than a 6,900# Mercedes EQS 580. When the sampling is expanded to larger areas or multiple stories then live load reductions come into play, but the 40 psf minimum live load still appears to be sufficient for the unreduced live load in parking structures.

Lastly, some have inquired about the weights of larger EV’s such as pickup trucks. The Ford-150 Lightning weighs about 6,500#, and the Tesla Cybertruck weighs in at about 6,700#, both of which are less than the 6,900# Mercedes EQS 580. The GMC Hummer EV Pickup is an outlier that tops the scales at 9,000#. But GMC Hummers represent only a fraction of 1% of vehicles on the road today. So, the GMC Hummer EV Pickup continues to beg the question as to whether it will be parked in all the stalls and lined up bumperto-bumper in the drive aisles in a typical parking structure. Furthermore, the experience of most parking structure patrons is that the number of large pickup trucks is few and far between. Also, not to be overlooked is that these vehicular loads are service-level and are multiplied by a live load factor of 1.6 for ultimate strength design analysis, in contrast with the dead load of the structure that is multiplied by a dead load factor of 1.2 for ultimate strength analysis.

For further consideration of this topic, we would encourage our readers to secure a copy of an excellent article featured in the July 2024 edition of Structure Magazine entitled, Electrical Vehicles and Parking Structures, by Leslie Jo Hurwitz, P.E., Brian Fisher, P.E., and Carl Schneeman, P.E. Their research is extensive and addresses other considerations while arriving at similar conclusions.

Nitterhouse Concrete Products, Inc. (NCP) in Chambersburg, PA, is a family-owned company serving the construction industry since 1923. Give us a call at 717-267-4505 or visit our website at www.nitterhouseconcrete.com for information on more quality precast, prestressed products to meet your design and construction needs. Choose with confidence and make NCP your single source for precast – what you need when you need it.