A question posed to us at Nitterhouse Concrete Products, Inc. (NCP) with increasing frequency regarding the design of parking structures is whether it is advisable to store snow on the roof level until it naturally melts during the spring thaw. Loading from temporary snow storage is unpredictable by its very nature and is cause for concern for long-term serviceability issues and the potential for structural failure. The International Building Code (IBC) provides no directive on the minimum loading requirements for temporary snow storage, likely because it is influenced by design assumptions and activities over which there is little control. A secondary reason is that the weight of piled snow is significantly greater than the typical loads for which parking structures are designed, and accommodation of piled snow would demand premium pricing of the parking structure. Not only would the structural design and sizing of the double tees be directly affected, so would the spandrels, beams, columns, and walls as the gravity load migrates to the foundations (which would also increase in size and cost).

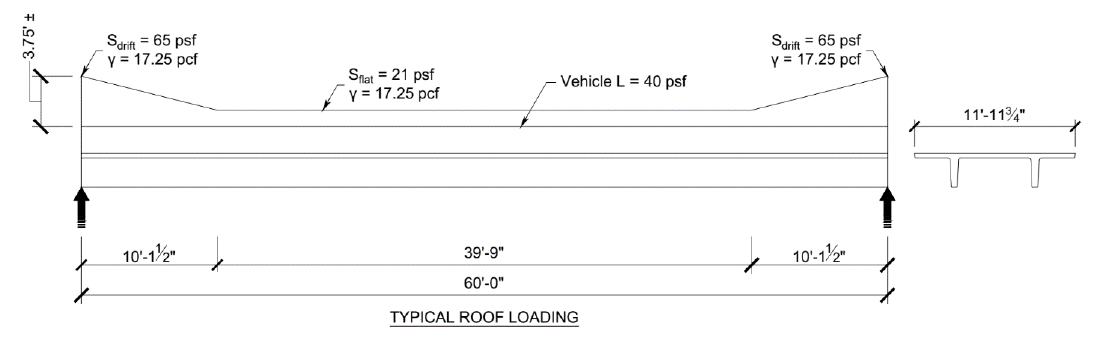

Below is a diagram of the typical roof loading for a parking structure in Philadelphia, PA. The ground snow (Pg) is 25 psf, and the thermal factor (Ct) is 1.2 because it is an unheated structure. The model accounts for a vehicular live load of 40 psf, a flat roof snow (Pf) of 21 psf, and drifting snow at the parapets. The parapets are assumed to be 3.75’ high, so the depth limit of the drifted snow and flat roof snow is also 3.75’. While these loads are not algebraically added to arrive at a “worst case scenario”, they can occur concurrently per the appropriate IBC-prescribed load combination criteria. For example, the following service load combinations are prescribed by IBC 2015 in keeping with ASCE 7-10…

- D + L

- D + S

- D + 0.75L + 0.75S

For the model shown above the controlling service load combination is D + 0.75L + 0.75S, resulting in a service load bending moment due to vehicles and snow of 254’K on the 12’-0” wide double tee shown. This is the equivalent of a 47.0 psf uniform load over the entire 60.0’ span and is representative of typical service loading for parking structures in the greater Philadelphia area.

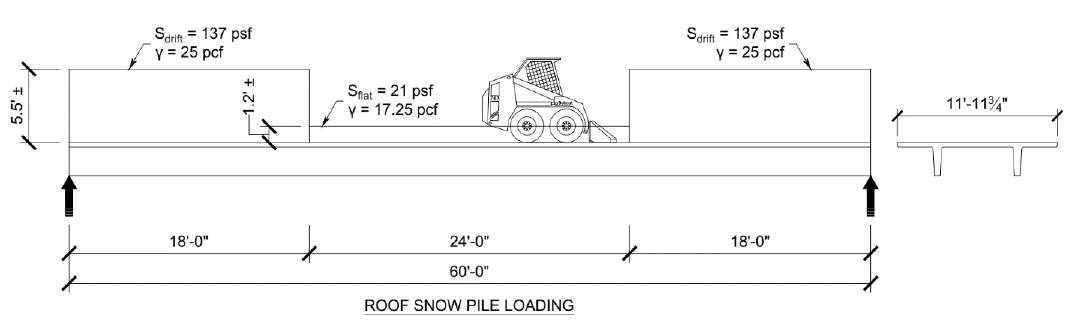

Because there is no IBC-prescribed criterion for temporary storage of snow on the roof level of parking structures assumptions need to be made for comparative purposes. Consider, for example, a possible scenario of piled snow in the parking stalls with a single-event snow accumulation in the drive aisle. We will also assume there is no vehicular loading on the roof level except snow removal equipment. We will also assume the snow removal equipment essentially maneuvers within the 24’-0” drive aisle and has a weight equivalent to that of the snow it is clearing. The density of snow is variable depending upon how much it is packed. While under “normal” conditions the design density for snow at this location is 17.25 pcf, packed snow or snow with a higher water content can be 25 pcf to 30 pcf or greater. Since there are relatively few limitations as to how high snow can be piled using a small front-end loader, the magnitude of loading from snow piling is also unpredictable. Furthermore, the duration of time over which the snow is piled and subject to absorbing additional precipitation increases the snow’s density, thus increasing the loading. As shown on the diagram below, assuming a density of 25 pcf at a depth of 5.5’ the weight of the snow pile is 137 psf. Because the loading is entirely caused by piling snow the only service load combination that will be considered is D + S to achieve an equivalent bending moment due to snow of 338‘K on the 12’-0” wide double tee shown. This is the equivalent of a 62.6 psf uniform load over the entire 60.0’ span.

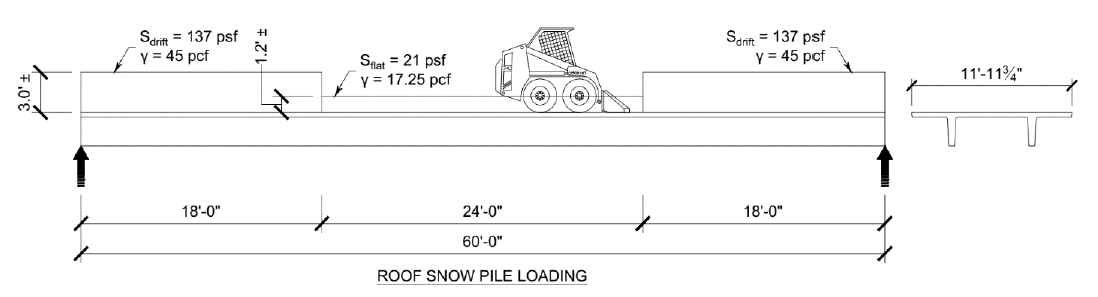

In addition to the concern about controlling the height of the piled snow is the density of the piled snow as briefly mentioned above. In the previous example we assumed a unit weight of 25 pcf, but plowed, wet snow can achieve a unit weight of 45 pcf, while a mixture of snow and ice can approach 60 pcf. These conditions can easily occur if drains are blocked and ice accumulates. As shown on the diagram below, the equivalent 62.5 psf snow loading over the entire 60.0’ span only permits “piling” the snow for about 3.0’ high for snow having a unit weight of 45 pcf, and if the piled unit weight achieves a density of 60 pcf the pile is only 2.3’ high! Most observers would agree that neither of these conditions constitutes “piling” of snow and is no practical value.

The conclusion of all this is that the variables are highly variable, and the probability of structural problems or even failure increases significantly with a high variability in load demand. It is imperative, therefore, that drains remain operational and that removal of snow needs to be given careful attention. There must be clear paths for water to reach the drains. Small style loaders with shoes or rubber guards that prevent direct contact with the deck surface are critical to minimizing damage to double tee flanges and expansion joints that might be incorporated into the deck. Double tee flanges are designed for IBC-prescribed concentrated loads of 3,000 #, so the weight of the equipment and any snow being conveyed must not exceed this amount on any of its wheels. NCP recommends preplanning by the architect and engineer-of-record to incorporate a snow gate(s) through the parapet to provide access for removal of the snow to the ground where it can safely be piled or hauled away. Snow gates are best placed in non-loading bearing spandrels. If this is not possible, they can possibly be in load-bearing spandrels with spans not exceeding about 24’-0”, but it is highly advisable to check with NCP’s Engineering Department to see if this is structurally feasible.

Nitterhouse Concrete Products, Inc. in Chambersburg, PA, is a family-owned company serving the construction industry since 1923. Give us a call at 717-267-4505 or visit our website at www.nitterhouseconcrete.com for information on more quality precast, prestressed products to meet your design and construction needs. Choose with confidence and make NCP your single source for precast – what you need when you need it.

Contact Nitterhouse Concrete Today