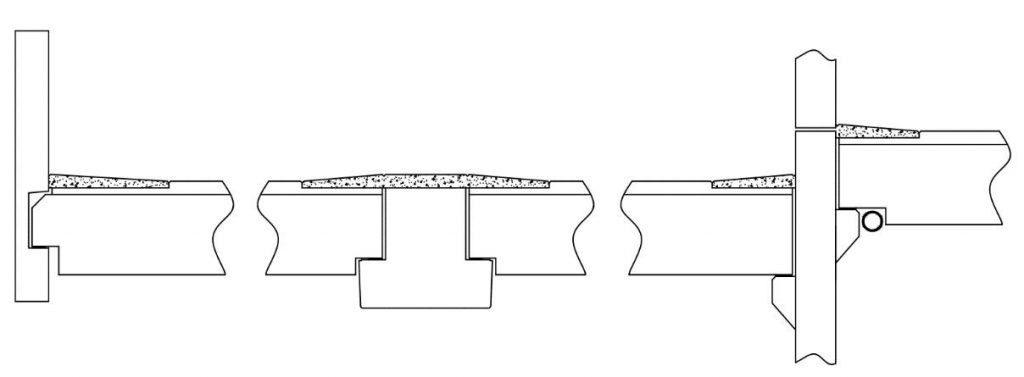

It is no surprise that the double tee is the workhorse of precast, prestressed concrete parking structures, and one of the most commonly found features is the use of dapped stems. Stem daps are typically found at exterior spandrels and interior inverted tee beams as shown in Details 1 & 2 below.

On occasion engineers and architects have detailed extended stem daps as shown in Detail 3 to accommodate pipe runs, especially along the interior litewall panels when story heights are limited and clearances are tight. Nitterhouse Concrete Products, Inc. (NCP) does not recommend this practice and advises that it be avoided whenever possible, suggesting that other means be investigated to address the lateral pipe runs. Reentrant corners in all building materials are stress-raisers, and double tee stem daps are no exception. Furthermore, it is a basic premise of reinforced concrete design that the concrete will crack as the connection is loaded and the reinforcing steel develops tensile stresses. While these cracks are often “tight” and sometimes undiscernible, they are nonetheless present, and will increase in width under additional loading and subsequent straining of the reinforcement. Designers and building owners are sometimes mistaken in thinking that because double tees are prestressed they will be entirely crack-free, forgetting that both extended stem daps and conventional stem daps are nearly always in a region above the level of the prestressed strands and designed using conventional reinforced concrete analysis. Some degree of cracking is to be expected, and the cracks in extended stem daps will be even more visibly pronounced due to an internal mechanism resisting large forces over short distances. For this reason, specifications should not be written to prescribe crack-free concrete, nor should there be an expectation of crack-free concrete in this region.

The design of dapped-end bearings for beams and double tees is covered thoroughly in the PCI Design Handbook (PCI MNL-120). There are several potential flexural and shear failure modes to be investigated, all

of which consider the presence of cracks described as…

- Direct shear at the junction of the dap and the main body of the member

- Diagonal tension emanating from the reentrant corner

- Diagonal tension in the extended end

- Diagonal tension in the undapped portion

Concrete design was based upon “working stress” (i.e.: service level) theory for many years. The yield point of the reinforcing was considerably lower than is used today, and the stress in the reinforcing under service loads was typically low. The low steel strain and that of the adjacent concrete minimized cracking. The advent of strength design (i.e.: plastic design) along with the use of reinforcing steel having a higher yield point the stress and strain levels in the reinforcing and surrounding concrete has increased, resulting in greater cracking. It is important to understand that the presence of such cracks is not necessarily indicative of structural failure or compromised serviceability. Accordingly, they should not be cause for rejection or unnecessary “repairs” that are unsubstantiated by analysis or testing.

Nitterhouse Concrete Products, Inc. in Chambersburg, PA, is a family-owned company serving the construction industry since 1923. Give us a call at 717-267-4505 or contact us online for information on more quality precast, prestressed products to meet your design and construction needs.

Contact Nitterhouse Concrete Today