Precast, prestressed hollow-core slabs have been reliable and frequently chosen construction components for over fifty years. Designers, contractors, and owners appreciate its high-performance benefits such as year-round construction, fast-track site erection, low maintenance, and long-term durability, making it a preferred choice for floor and roof construction in hotels, apartments, schools, prisons, and a multitude of commercial building applications. Automated casting provides high quality, mass production, and value pricing, that along with other important structural components deliver high-performance facilities for owners and developers everywhere. Precast, prestressed concrete lends itself to customization and creativity, but economic considerations suggest these must be balanced with the benefits of automated casting processes. Unnecessary and excessive detailing introduces more manual labor, thus increasing the unit cost. This paper addresses some of those details that can easily increase the unit cost by an order of magnitude of 15% to 20%.

It is common for precast, prestressed hollow-core slabs to be detailed by architects and engineers to have filled cells, or partially filled cells, for various reasons such as increased shear capacity, anchorage for embedded hardware (ex: weld plates and lifting inserts), anchorage for supplemental mild steel reinforcing bars, etc. These design and detailing practices are used through a wide range of proprietary hollow-core slabs, and NiCore™ Planks from Nitterhouse Concrete Products, Inc. (NCP) are no different. But just because a practice is common does not exempt it from being troublesome, and sometimes even problematic.

Perhaps one of the greatest misconceptions of designers is that filled cells are formed and cast monolithic with the rest of the hollow-core slab cross section. This could not be further from actual practice, so understanding the process by which cells are typically filled solid is crucial to reasonable expectations of performance and constructability.

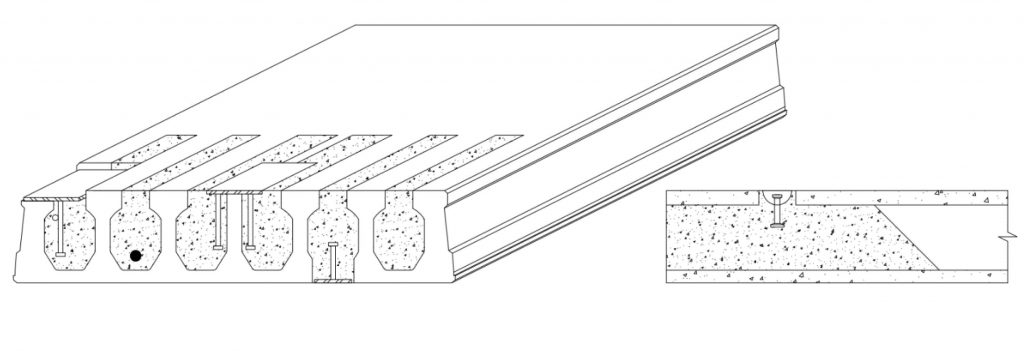

- The NiCore™ Plank sections are machine-cast for the entire 400’ length of the casting beds. This is comprised entirely of a dry-cast concrete mix. It is stiff enough to be self-supporting without the need of siderails as would typically be needed with wet-cast concrete. While some hollow-core sections are wet-cast, the bulk produced in America today are not.

- Locations of filled cells are measured out and manually cut into the dry-cast concrete section using trowels while the dry-cast concrete is still in its plastic state. Only the top flange is cut out and the dry-cast concrete removed and disposed for filled cells receiving top embedment hardware. Similarly, long reinforcing bars cast into NiCore™ Planks require that the top flanges over the cells in which the reinforcing bars are placed be cut out for the length of the rebars. If embedment plates are detailed in the bottom, the bottom flange also needs to be manually cut out and the dry-cast concrete is removed and disposed. The latter procedure completely opens the cross section through to the steel casting bed.

- Because the cells are approximately 5½” wide there is very limited space with which to perform this hand-work, especially for 10”, 12”, and 16” thick NiCore™ Planks.

- The next step is to place end dams as required into the open cells to contain the fill concrete.

- Bottom embedment plates are then placed into position and fill concrete is carefully placed above and around the embedment plates. Longitudinal reinforcing bars are chaired into position on top of the bottom flange, and the fill concrete is placed into the open trough. If there are top embedded plates, they are then puddled down into the wet fill concrete.

- Even though the dry-cast concrete does not have all the characteristics of “hardened concrete”, placement of the fill concrete behaves similarly to fresh concrete cast against hardened concrete, much like the grout that is field-placed in the longitudinal grout keys or the grouted vertical cells in concrete masonry walls. While there is some bond at the interface of the materials it is not completely impervious to surface water from precipitation, hence the presence of water that sometimes becomes entrapped in the cells between fill areas.

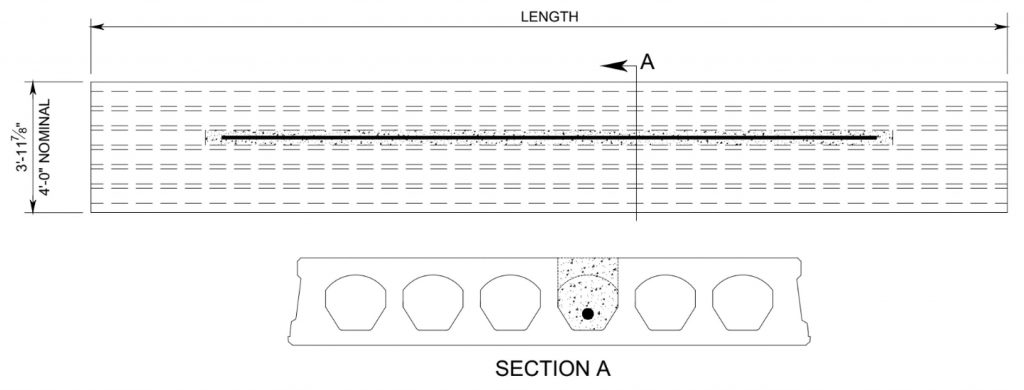

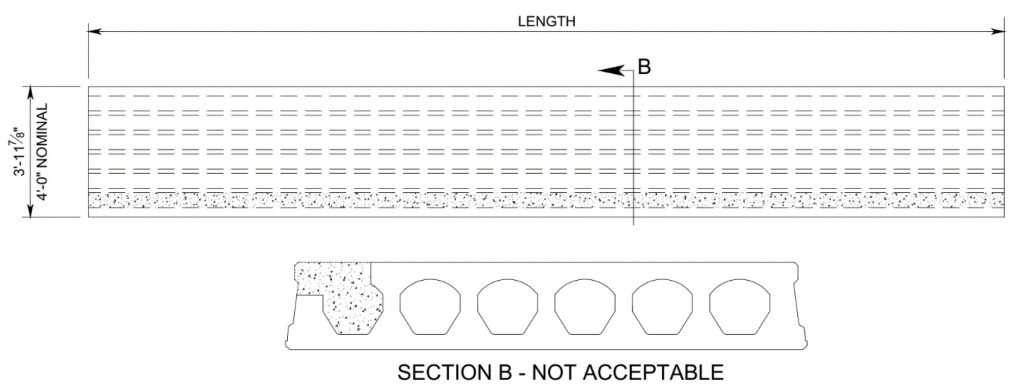

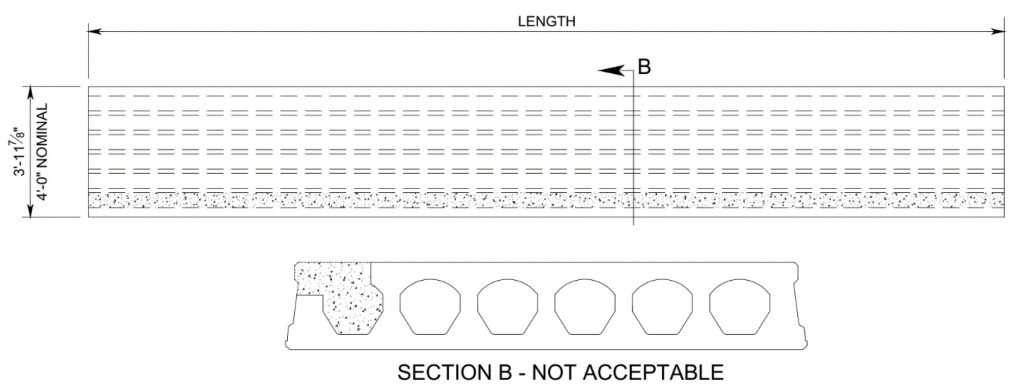

- Examples of filled cells are graphically shown below.

Having described the process by which items are embedded in the NiCore™ Plank and the cells are filled, there are still factors that need to be considered to maintain their integrity during handling, shipping, and while in service.

- As mentioned above, if a mild reinforcing bar is detailed it must be placed into a filled cell created by cutting out a trough the length of the rebar. Even smaller sized rebars must be placed in this same manner and cannot be “snaked” through a series of access holes because their placement would tear up the bottom flange while in its plastic state. Depending upon the thickness of the NiCore™ Plank the weight will increase an order of magnitude of about 10% to 20% and needs to be taken into consideration, not just for the NiCore™ Plank itself, but for the supporting structure.

- Sometimes designers show the top flange of the outer cell totally removed and the cell filled with grout in the field. This practice simply will not work because the “dangling” cantilevered portion can easily break off.

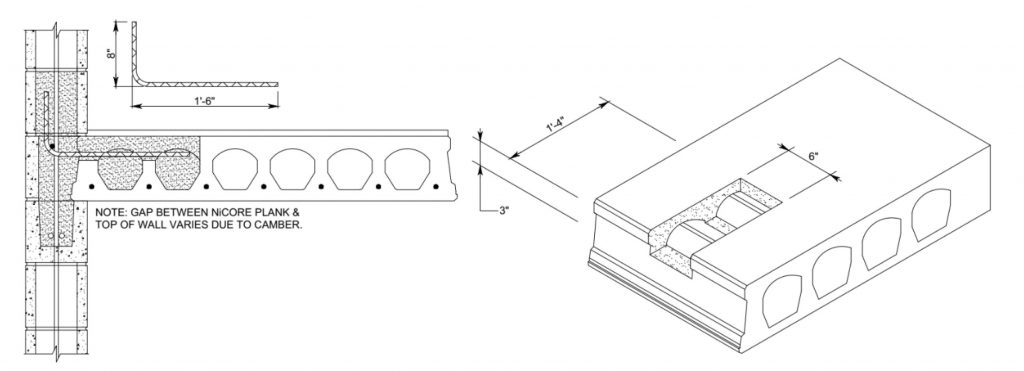

- By far the most common way to connect NiCore™ Plank to adjacent masonry walls is by detailing intermittent side pockets. This simple connection not only provides lateral bracing for the masonry wall but can also be used to drive diaphragm shear from the NiCore™ Plank into masonry shear walls. If the pockets shown are limited to a minimum spacing of 3’-0” they will not compromise the integrity of the NiCore™ Plank during handling. However, the most frequently detailed spacing chosen by designers is 4’-0” o.c.

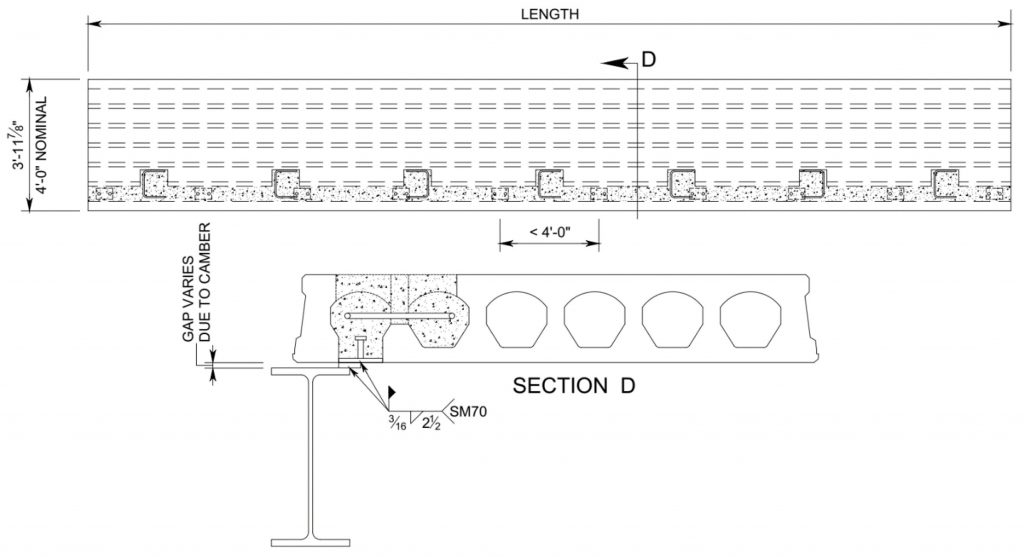

- Another common detail requiring weld plates and partially filled cells is for connections to structural steel beams running parallel to the NiCore™ Plank as shown below. If the weld plates are spaced no closer than 4’-0” o.c. there is no need for rebar “staples”. If, however, the weld plates are closer than 4’-0” o.c. the plastic concrete is not capable of supporting itself and rebar staples are required to tie the first cell back to the second cell because the NiCore™ Plank is vulnerable to longitudinal splitting into two pieces. To overcome this a series of rebar “staples” are grouted across the cell into neighboring cells as also depicted below. This procedure holds true for weld plates placed in top of the NiCore™ Plank as well.

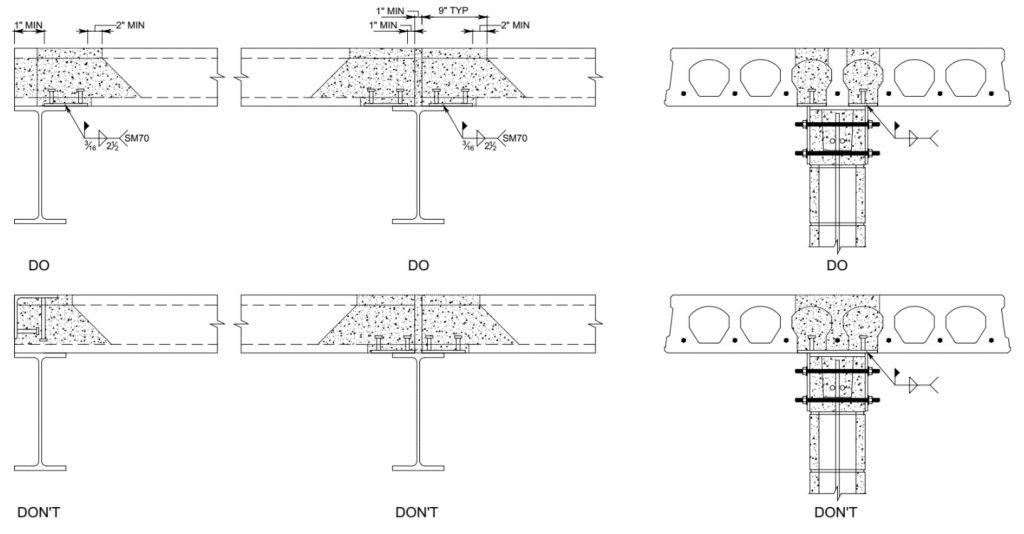

- Another very common use of weld plates and filled cells is at the ends of NiCore™ Plank bearing on structural steel. These plates can serve a dual function of providing lateral bracing to the compression flange of the beam and driving diaphragm shear from the NiCore™ Plank into braced frames or moment frames that laterally brace to the entire building structure against wind and seismic loads. Because NiCore™ Plank are cast continuously in 400’ long beds and saw cut to the detailed length, it is important that the weld plates be held at least 1” clear of the end of the plank to avoid interference with the crosscut saw. Another important detailing consideration is that large bottom plates cannot be cast into NiCore™ Plank because the automated casting process precludes their placement before the strands are placed & stressed, and the dry-cast concrete is cast.

We trust this narrative helps to provide a more complete picture of the production process needed to position embedded hardware and reinforcing in preparation for placement of the fill concrete into the cells.

Nitterhouse Concrete Products, Inc. in Chambersburg, PA, is a family-owned company serving the construction industry since 1923. Give us a call at 717-267-4505 for information on more quality precast, prestressed products to meet your design and construction needs. Choose with confidence, and make NCP as your single source for precast – what you need when you need it.

Contact Nitterhouse Concrete Today