Jump-To:

- What is Precast Concrete?

- What is Site Cast Concrete?

- Advantage of Precast

- Comparing Precast vs. Site Cast Concrete

- Examples of Precast Buildings

- Finding a Quality Precast Manufacturer

Precast concrete or site-cast concrete? Asking yourself this question is essential for any construction project, as the choice largely depends on your needs.

Precast concrete is incredibly versatile because on-site concrete pouring is custom to the build. Its affordability, quality and longevity stand out against on-site competitors. Precast concrete has established itself as the preferred approach to concrete construction.

The demand for precast concrete in the U.S. is on the rise, with a predicted growth of 6.4% from 2022 to 2028. Whether you want to embark on a new construction or stay on top of the latest building and fabrication trends, this guide will put the differences between the two approaches into perspective.

What Is Precast Concrete?

Precast concrete gets poured into premade molds, molded over rebar or wire and cured off-site under ideal conditions in the manufacturing plant. The manufacturing process features controlled production, versatile design, durable products, quick construction and several sustainability benefits. Once hardened, the precast concrete is ready for use on the job site, where workers assemble it into the desired structure. This material is valuable for its high-quality, durable and efficient solutions.

What Is Site-Cast Concrete?

Site-cast concrete, also known as in-situ concrete, gets manufactured on-site. One of its advantages is that it does not need to travel to the job site, which is why on-site is usually the best solution for a building requiring large, unwieldy and custom concrete molds. Some forms are too large to fit on the back of a flatbed truck. Conversely, the savings from precast concrete scale, meaning that in-situ concrete may be more cost-effective for a small structure. Additionally, site-cast concrete is usually the preferred option for buildings that need to be “earthquake-proof.”

Advantages of Precast Concrete

Factory control equals factory quality. Concrete strength and quality rely on the curing process. Factors like climate control are a big part of that. It adds more confidence in the precision of the mold and fabrication, adding strength and consistency to the cast. Consider these benefits of precast concrete.

- Factory efficiency: Factory-cast concrete is more cost-efficient and expertly manufactured. Each cast requires less labor, thanks to fabrication using assembly line techniques.

- Versatility: While customization has its limitations, precast concrete offers many motifs, colors and finishes, along with smaller precast architectural elements.

- Economies of scale: As precast concrete uses standard forms, you can mass-produce slabs, improving the economies of scale. Moreover, this standardization creates fixed pricing, enabling you to budget construction costs accurately.

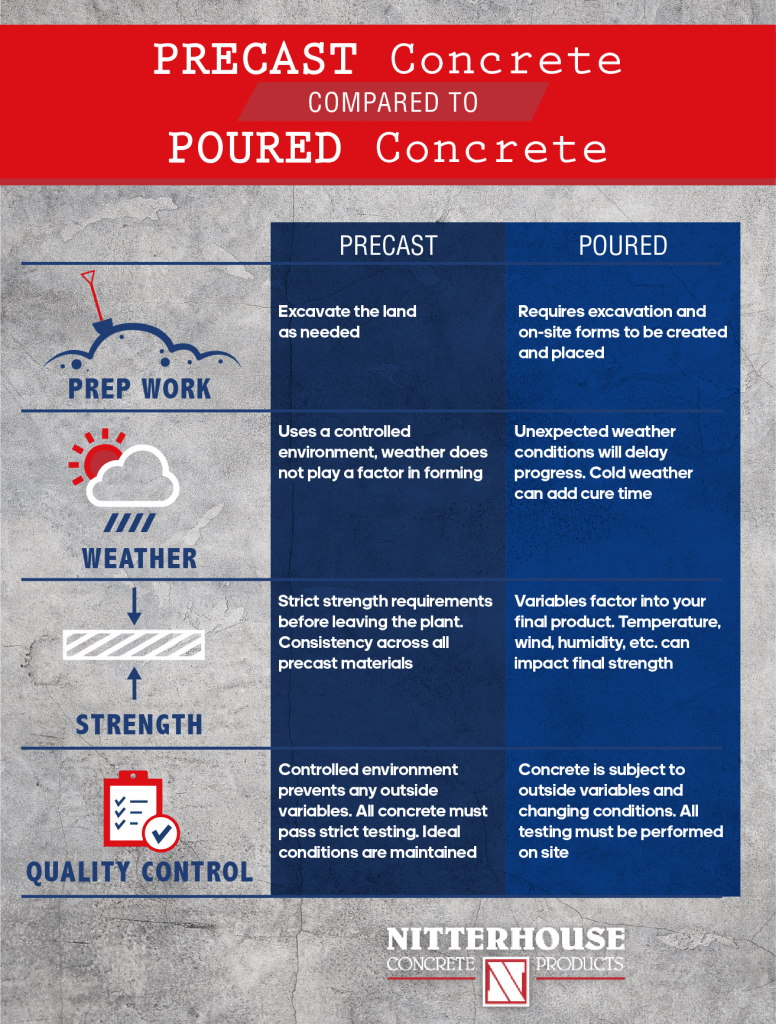

- No on-site formwork: The formwork required for on-site concrete pouring is time- and space-intensive. On-site curing also requires leaving forms in place for extended periods, taking up space on site. You must watch the weather forecast, as those forms need to cure under specific conditions. In other words, on-site formwork is a logistical headache. By using factory casting, you can avoid all the stress of coordinating on-site skilled labor and logistics.

- Efficient and sustainable material use: You will maximize material efficiency by using precast concrete. Precast concrete’s precision reduces material waste. It is much harder to accomplish this on-site, as concrete preparation’s labor inefficiency motivates contractors to mix more concrete than needed, just in case. Furthermore, concrete is a recyclable material, meaning you can build green efficiency into your precast concrete construction materials.

Environmental Considerations When Using Precast and Site-Cast Concrete

Sustainability in construction focuses on the products and techniques you use in your build. Precast and site-cast concrete production has environmental implications. Cement manufacturing contributes up to 8% of global CO2 emissions and can deplete resources, depending on the raw materials used. The primary considerations are carbon emissions, waste management and resource efficiency. Each concrete production method has distinct impacts.

- Manufacturing: Since precast concrete manufacturing happens in controlled conditions, it produces less waste, leading to better resource use and lower emissions. Site-cast concrete can adversely impact the environment and increase carbon emissions if workers do not correctly manage on-site energy and water use. Improper waste management can also harm the environment.

- Transport: While transporting precast concrete creates emissions, you can weigh this against its sustainable manufacturing. In contrast, on-site casting does not need transportation.

- Concrete mix design: Concrete production is more sustainable than cement production as it uses a chemical hydration process. The precast mold is reusable, and this process’ efficiency ensures there is less chance of on-site delays that incur extra energy usage.

- Materials: Concrete uses abundant, naturally occurring resources like gravel, sand and rock. This aggregate can also incorporate recycled materials like excess spillage from manufacturing or old concrete from demolition sites. The water-cement ratio is between 0.36 and 0.38, which is low compared to cement.

Precast concrete offers a distinct advantage as more builders chase green ratings for energy savings and good PR. Despite the need for transport, precast concrete involves less waste, better resource allocation, recycling abilities and overall lower carbon emissions.

When to Use Precast Concrete Over Site-Cast Concrete

The best way to illustrate precast concrete’s superiority is to highlight the differences between precast and site-cast concrete. Here are some contrasts between the two methods placed side by side.

- Quality control: The factory workers who manufacture precast concrete can maintain ideal conditions and exact measurements throughout the process. With site casting, you are at the mercy of fluctuating humidity and temperatures. The result is an inferior product even under the most ideal conditions.

- Labor efficiency: Precast is much more labor-efficient. Workers have access to tools and machinery that are unavailable on the job site. In comparison, site casting involves manual work that increases labor costs and overheads.

- Curing conditions: Curing conditions for precast concrete are factory-controlled. Workers can speed them up while maintaining the product’s strength and quality. That isn’t the case on site. While you can take steps to accelerate on-site curing, they are challenging and generally not worth the logistical hassle and costs. Furthermore, they run the risk of lower-quality concrete, as delicate variables are hard to account for. If you need accelerated curing, precast is the only way to move forward confidently.

- Full strength: Precast concrete’s hardening process occurs in the manufacturing plant, which can delay construction and increase costs. It saves more money and time to have fully hardened concrete slabs ready for placement when they arrive on site. Additionally, factory workers test precast concrete’s strength during quality control inspections, so you do not need to conduct on-site strength tests.

- Cast ahead of time: Precast concrete is ready for immediate placement on a construction site. Because of the space and labor required for on-site casting, you generally have to stop construction while you wait for your materials to be ready.

- Weather: An unexpected rainstorm can grind on-site casting work to a halt. If it is raining when your precast slabs arrive on site, you can still lift them into place.

- Insulation: Because precast concrete is factory-made, you can incorporate elements like insulation, which is impossible with site-cast concrete. Adding insulation materials within the concrete slab can save labor and architectural design space when constructing a building. Rather than hanging and lining the building interior with insulation, the slabs you lift into place have the insulating power of traditional concrete with additional hung insulation.

Specialized reinforcement: You can add specialized structural reinforcements to precast concrete. These are crucial for some projects, as they allow the panel to bear loads that traditional poured concrete cannot. Decreasing the material needed to make a building structurally sound can lower overheads and use resources efficiently. - High-strength concrete: Specialized high-strength concrete requires exacting conditions for mixing and curing. You cannot control these conditions on a construction site. However, because factory construction allows for heightened environmental control, you can use specialty high-strength concrete to create unique architectural designs.

Examples of Precast Buildings

Precast buildings can be beautiful, efficient and durable. Here are some architectural projects that have become a reality with precast concrete.

- Charter Arts School — PA: There were two primary concerns when constructing this building using precast concrete — design and safety. Design was crucial for an art school. The building had to speak to modern aesthetics and create a learning environment conducive to exploring the possibilities of visual art. But as a school, student safety was paramount. That’s why the builders opted for precast hollow core planks. This system has a superior fire resistance rating. Also, the construction reflected the organization’s commitment to sustainability.

- Hershey Medical Center — PA: This brand-new building’s design had to blend in with the rest of the hospital campus. While the team still used precasting throughout, it involved a custom concrete blend. Because Hershey Medical Center is a rapidly growing, invaluable medical resource for the surrounding area, building schedules were quick and the entire project wrapped up in four months.

- Target Retail Center — PA: New retail constructions are often part of large-scale development in which land is plentiful. However, urban retail constructions, like this new Target Retail Center, require working within constrained areas with limited available land. As a national brand representative, the building also had to reflect its parent company’s architectural branding. Thus, construction workers placed the parking area below the store, requiring superior strength precast elements. Simultaneously, the project had to finish quickly to avoid disruptions to the surrounding neighborhood. Again, the efficiency of the precast was essential for getting this job done on time.

Contact Nitterhouse Concrete for Precast Concrete

If you are building in the mid-Atlantic, look no further than Nitterhouse Concrete Products. Since 1923, we have provided superior concrete products to the region, partnering with large and small architects and construction companies to help bring their visions to life.

While you may still occasionally need to turn to site-cast concrete, precast concrete provides superior versatility, functionality, affordability and labor efficiency. If you aren’t yet using precast for your projects, it’s time to switch. And even if you are already familiar with the value, you may want to consider whether you are getting the attention you need from your manufacturing partner.

If you’re ready to take the next step and get the wheels moving on your future building projects, contact one of our experts for additional planning assistance.

Contact Nitterhouse Concrete Today