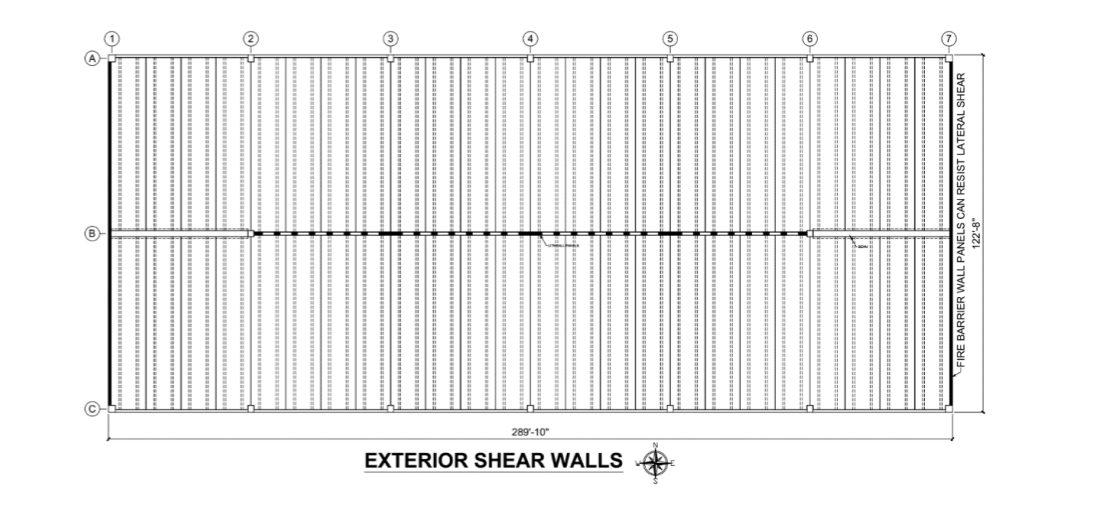

Lateral seismic and wind loads significantly influence the selection of structural framing for precast parking structures. While it is not always the case, seismic loading usually controls the lateral design because it is a direct function of the mass of the structure, and robust precast concrete structures are naturally more massive than many other building materials. The primary methods of resisting lateral loads in structures are “X” braces, moment frames, and shear walls. Shear walls are a very efficient solution for minimizing lateral drift and are commonly used in precast parking structures to resist lateral seismic and wind loads. Furthermore, shear walls need not be discrete components devoted exclusively to resisting lateral shear loads. The most efficient shear walls also resist gravity loading. Litewall panels are shear walls with punched openings that resist out-of-plane gravity loading from the double tees concurrently with in-plane shear loading. Similarly, fire barrier wall panels separating the parking structure from adjacent residential / retail structures can also resist out-of-plane gravity loading from beams concurrent with in-plane shear loading. These examples effectively demonstrate the multifaceted functions that different precast components provide, making them the preferred choice of parking structure owners and designers.

This narrative is intended to give architects and engineers a “high altitude” perspective of how the selection of precast framing affects other important functional and serviceability aspects of the parking structure, while we will address other important structural and construction considerations related to the design of the shear wall panels separately. We will see how the architectural selection of interior vs. exterior shear walls can significantly impact the openness calculations required by the International Building Code.

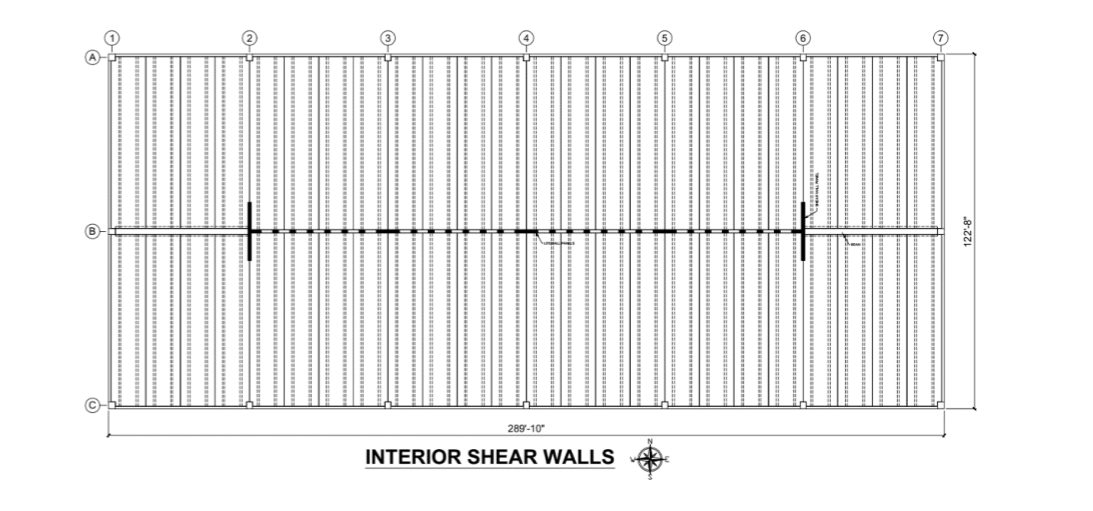

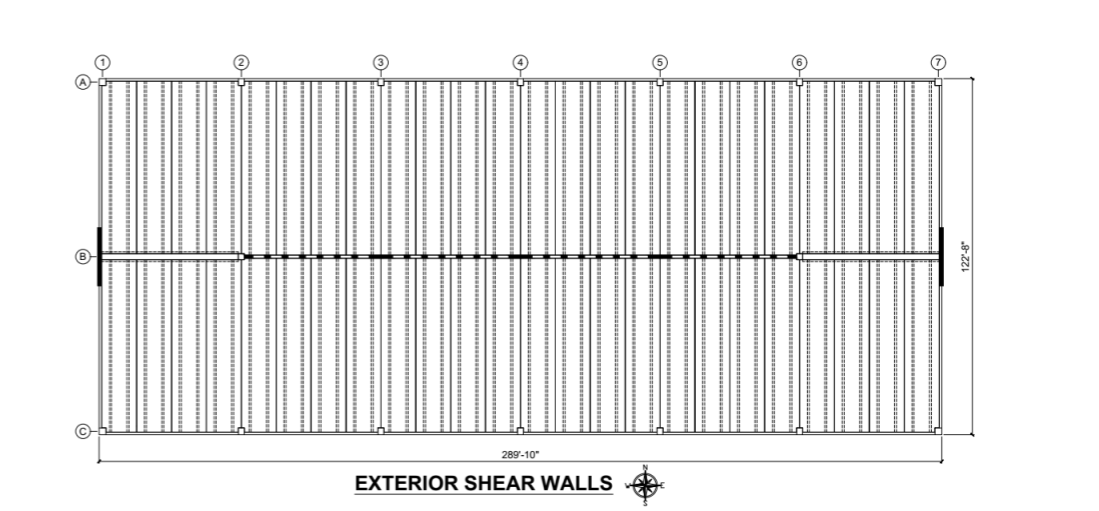

Observations of Shear Walls & Openness

Our attention is focused on the two (2) basic framing models shown below, but first, here are some observations…

- These models are deliberately simple to draw our attention to the basic principles.

- The stair and elevator towers are not shown. They are usually placed at the corners of the structure to take advantage of the parking “dead zones”. Sometimes they are also used to resist lateral loads, but they are not usually efficient for this purpose. The most efficient shear walls capture as much dead load as possible to counter the effects of overturning moments, a rare opportunity for stair and elevator panels. Furthermore, it is preferable to increase the flexibility of the towers by controlling their sizes and connections to avoid attracting undesirable volumetric forces while naturally directing the lateral loads to the stiffer shear wall components.

- The litewall panels along the Gridline B will serve to resist east/west lateral loads and will notcontribute to this narrative.

- This narrative is independent of any specific loads as determined by the structure’s seismic or wind region, soil profile, geometry, etc.

Advantages of Interior Shear Walls Include:

- The parking structure’s perimeter openness is optimal to help avoid mechanical ventilation throughout the service life of the structure when using interior shear walls.

- Diaphragm connections from the double tees can be made along both sides of interior shear walls, while collector connections might be needed to capture the diaphragm shears at exterior shear walls.

- It is normal to cast interior shear wall panels using structural gray concrete, while exterior shear wall panels will often require a more expensive architectural color and finish.

- The diaphragm chord reinforcement is significantly reduced when using interior shear walls in comparison with a diaphragm spanning the full length of the structure for exterior shear walls. In these models,

For exterior shear walls, Mmax at Gridline 4 = (0.5)(w){[(0.5)(289.83)-48.915]2 – 48.9152} = 3,412w

For interior shear walls, Mmax at Gridline 4 = (0.125)(w)(289.83)2 = 10,500w

The chord reinforcement for exterior shear walls is three (3) times more than for interior shear walls. - The diaphragm lateral drift is significantly reduced when using interior shear walls in comparison with a diaphragm spanning the full length of the structure for exterior shear walls. In these models,

For exterior shear walls, ∆max at Gridline 4 = (w)(5)(289.83)4 / 384EI = 91,878,126w/EI

For interior shear walls, ∆max at Gridline 4 = (w)(192) 2 [(5)(192)2 – (24)(48.915)2] / 384EI = 12,181,992w/EI

The diaphragm lateral drift for exterior shear walls is 7.5 times more than for interior shear walls.

Advantages of Exterior Shear Walls Include:

- Exterior shear wall panels can add aesthetic interest by breaking up the appearance of repetitious columns and spandrels. The use of architectural concrete, finishes, reveal patterns, thin brick, and other features can contribute to this. This is another fine example of using precast components to achieve both structural and architectural goals.

- Exterior shear walls offer improved torsional resistance to load eccentricities.

- Exterior shear walls provide improved visibility for both drivers and pedestrians for vehicles negotiating the end turns.

- Exterior shear walls enhance passive security inside the parking structure by reducing the number of hidden locations for lurking criminals.

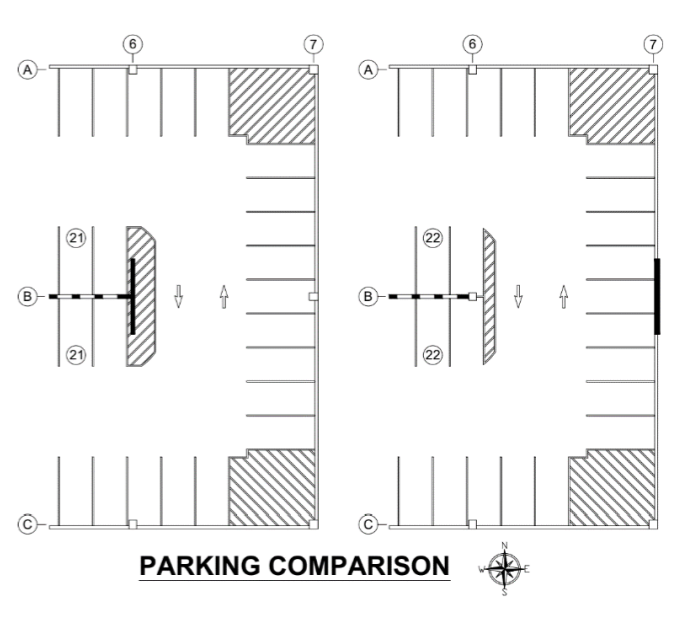

- Depending upon the available length of the litewall panels along Gridline B, when using exterior shear walls, the columns at Gridlines 2-B & 6-B sometimes permit additional parking spaces along both sides of Gridline B because they are not sacrificed by interior shear wall panels. In these models the parking count increases from 21 to 22 spaces on each side of the litewall panels.

As mentioned earlier in this narrative, in parking structures associated with adjacent “wrap structures” it is common for the precast fire barrier wall panels to also serve as shear walls. This is graphically shown below.

For further information on important structural and construction considerations related to shear wall selection and design, read Seismic & Wind Loading For Parking Structures – Shear Wall Design Considerations.

Contact Nitterhouse Masonry for Precast Concrete Products

Nitterhouse Concrete Products, Inc. (NCP) in Chambersburg, PA, is a family-owned company serving the construction industry since 1923. Give us a call at 717-267-4505 or visit our website at www.nitterhouseconcrete.com for information on more quality precast, prestressed products to meet your design and construction needs. Choose with confidence and make NCP your single source for precast – what you need when you need it.

Contact Nitterhouse Concrete Today