Concrete is a porous material that absorbs water and as a result, a floor or roof comprised of hollow-core planks is not a waterproof system by itself, and NiCore™ Planks are no exception. This is true not only for the finished system, where planks exposed to the elements must be protected by a permanent waterproof membrane, but also during construction of the building where the planks will absorb rain water or snow melt until the building is dried in. This absorbed water tends to collect and become entrapped within the hollow cores of planks between the solid grouted ends or between cast-in embedments such as weld plates or lifters. For typical planks with upward camber at midspan, the water will tend to drain towards the bearing ends and settle beside the solid grouted ends.

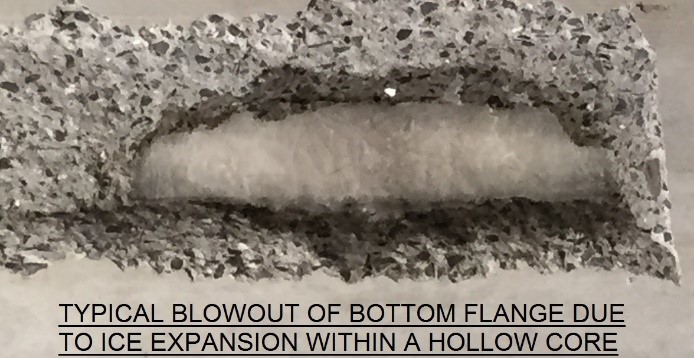

It is very important that this entrapped water be drained from the plank via weep holes drilled in each of the hollow cores near the bearing ends to allow the water to drain, as well as between solid filled areas for embeds and grouted connections. Best practice is to provide these weep holes prior to water collecting so that water can immediately and continuously drain from the weep holes. This is especially important during cold weather, as entrapped water can freeze in an unheated structure and expand, usually causing the flange of the plank to blow out below the ice (see example photo below). In most cases, the damage is primarily a cosmetic issue and can be repaired by filling the area solid with concrete or grout, but the most severe cases of ice damage can require extensive structural rehabilitation. It is a mistake to assume that planks erected during the spring, summer, and fall seasons are not vulnerable to this condition. Entrapped water during these seasons has been known to eventually migrate through the bottom soffit, resulting in damage to paint or other finish materials.

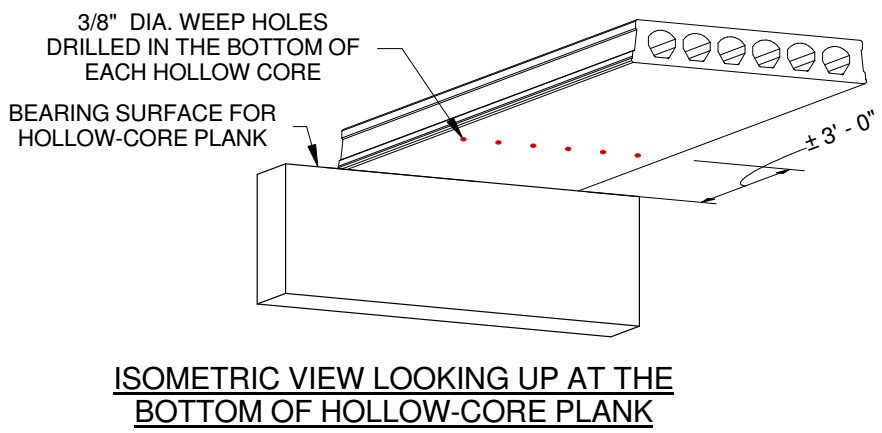

Nitterhouse Concrete Products, Inc. (NCP) recommends that 3/8” diameter weep holes located approximately 3’-0” from the face of bearing in each core at each of the bearing ends of the plank (see detail below of one end of a plank for reference) be provided. It is also important that weep holes be maintained by the general contractor at the job site to ensure that they do not become plugged with ice, thus rendering them ineffective. After the building is dried in but prior to finishes being installed, the weep holes will need to be patched or caulked by and at the expense of another trade or the general contractor to prepare the surface for paint when the underside of planks are exposed to view. Where not exposed to view, the weep holes can remain open for the life of the building.

Weep holes can either be drilled in the field by the general contractor shortly after NiCore™ Plank are erected, or NCP can install them in the plant during the manufacturing process at an added cost. While some of our customers prefer to drill the weep holes in the field themselves, we find that most of our repeat clients elect to have them installed in the plant prior to shipping, as they have found this to be the best value and provide the best performance of the weep holes to ensure product durability. This is especially critical considering the new OSHA Regulation CFR 1926.1153 regarding respirable crystalline silica (silica dust). Small dust particles occur when practices such as drilling, grinding, and cutting concrete are performed. Inhalation of silica dust over an extended period can result in silicosis and lung cancer. While OSHA set limits on crystalline silica dust exposure as early as 1971, new regulations went into effect on September 23, 2017 for all construction sites. Dust control measures and respiratory protection include water-delivery systems for wetting the dust as it is created, vacuum dust collection systems for removal of dust, use of half-masks with filtering face pieces, medical surveillance, etc. It is not within the scope of this article to exhaust all the OSHA regulations and new construction practices, but simply to bring to light the value of paying for NCP to include weep holes during the manufacturing process in lieu of introducing these new OSHA regulations and mandatory controls on the construction site when drilling weep holes. Accordingly, NCP recommends that all NiCore™ Planks be purchased with the inclusion of factory-installed weep holes and urges our clients to discuss this option with their sales representative.

Nitterhouse Concrete Products, Inc. in Chambersburg, PA, is a family-owned company serving the construction industry since 1923. Give us a call at 717-267-4505 or contact us online for information on more quality precast, prestressed products to meet your design and construction needs.

Contact Nitterhouse Concrete Today